Featured Work

TERA

TERA

AN EARTH HABITAT

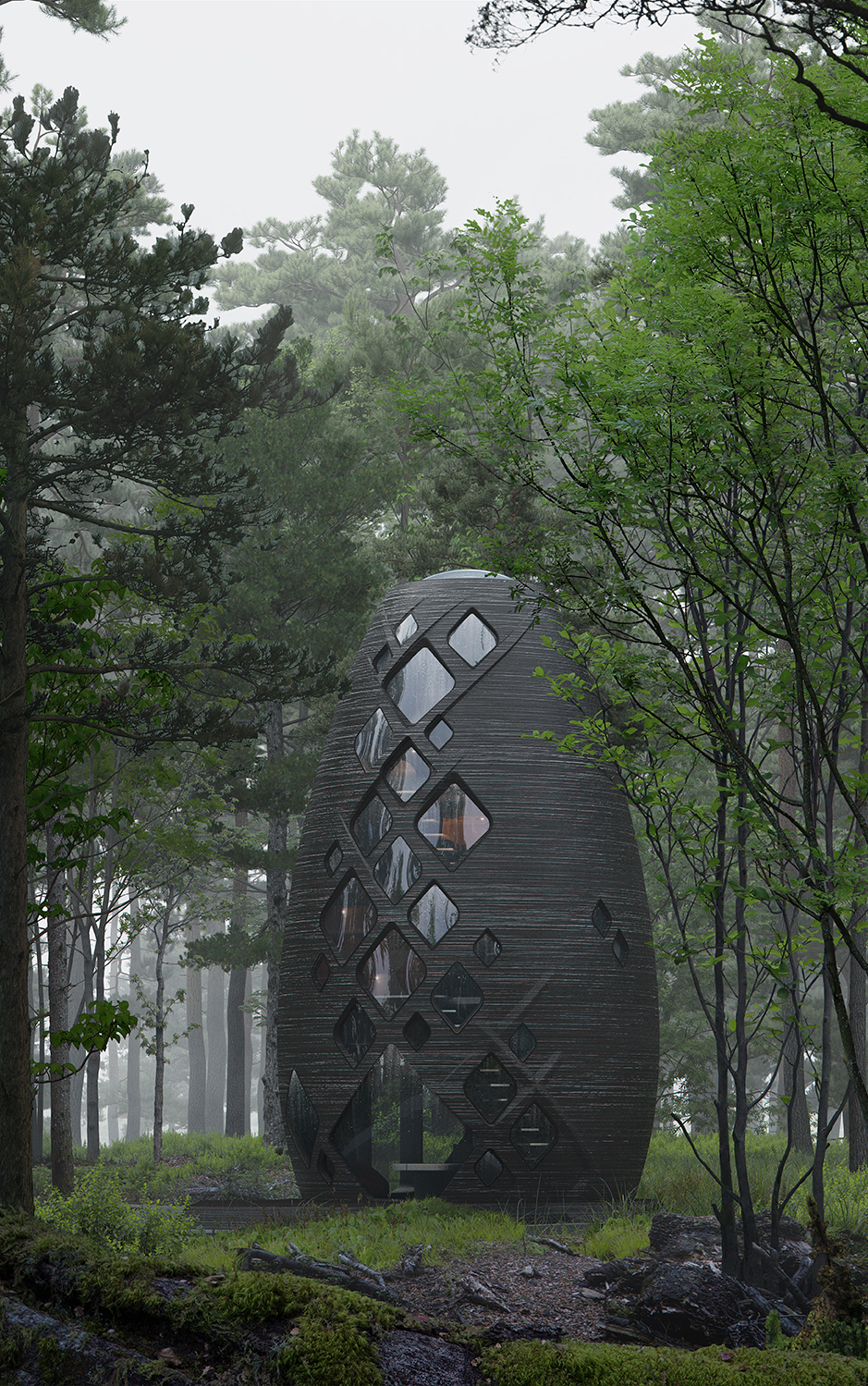

Built with NASA award winning technology, TERA is a forward thinking terrestrial habitat inspired by the shape of our Martian habitat, Marsha. Tera offers a sustainable solution for building on this planet, while advancing the technologies for living on another. I lead the design team in this project.

TERA Crowdfunding

We set up a successful fundraising Indiegogo campaign for Tera’s upstate new york construction.

Click here

for TERA fundraising indiegogo champion page

Built with NASA award winning technology, TERA is a forward thinking terrestrial habitat inspired by the shape of our Martian habitat, Marsha. Tera offers a sustainable solution for building on this planet, while advancing the technologies for living on another

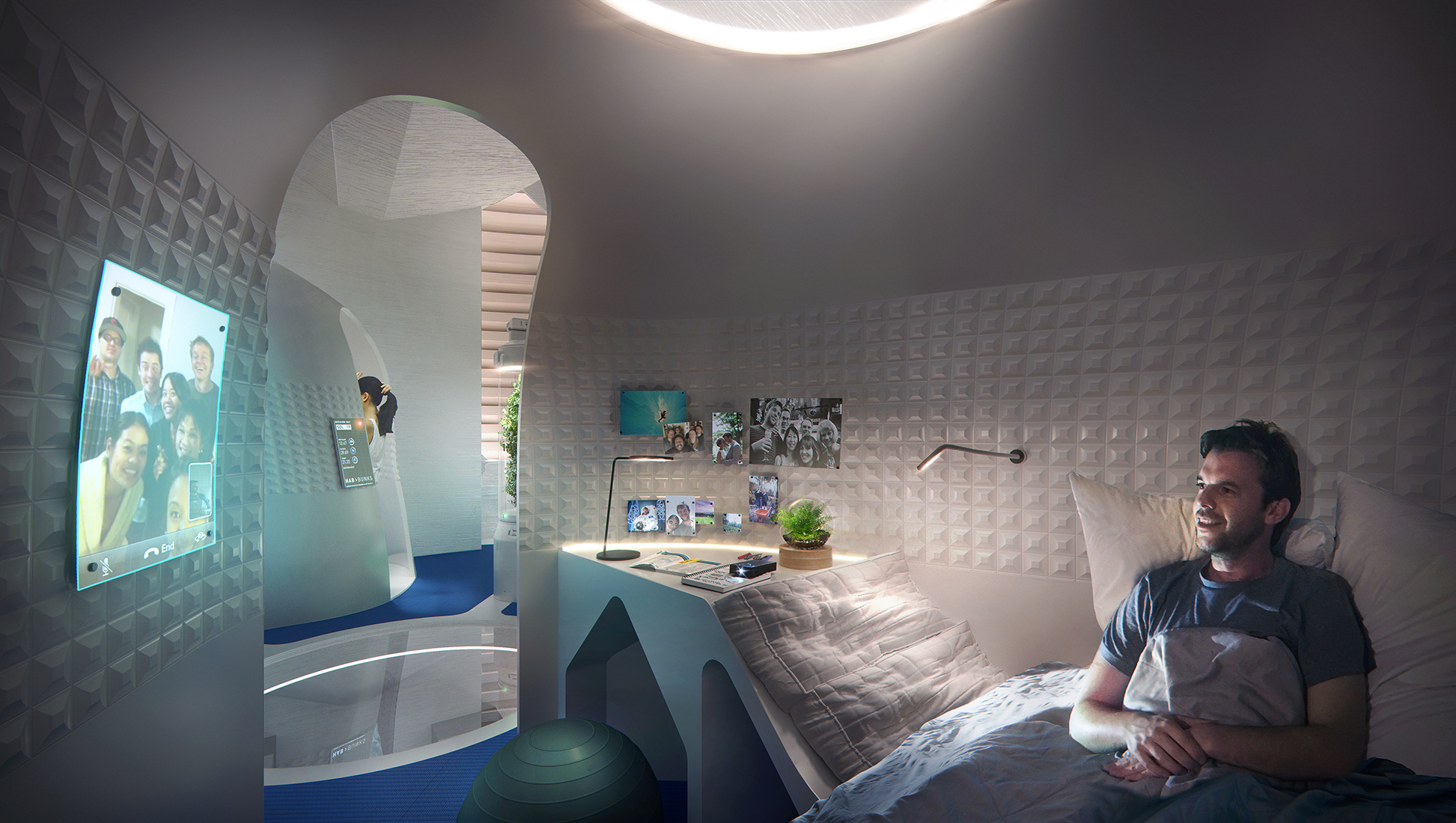

TERA’s rich and playful interior, made of birch and poplar, evokes that of a tree-house. Free of pre-defined rooms, TERA’s various activity areas are perched on, and nestled in, a spiraling form emerging from the landscape. TERA’s open plan maximizes daylight and air circulation—further enhanced by energy efficient LED lighting and underfloor heating to provide year-round comfort

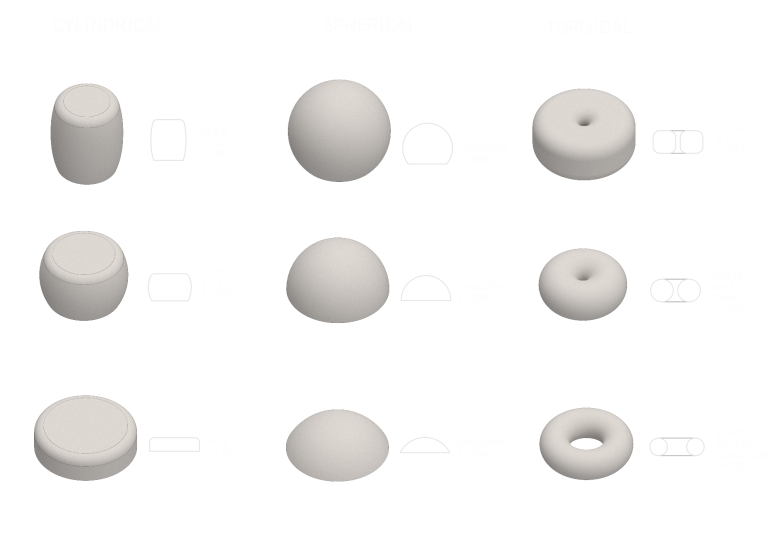

We studied different porosities and profiles based on our material property, printability and possible construction equipment

The first floor includes areas for sitting and food preparation, an

herb garden, bathroom and storage. Along the way to the second floor and embedded in

the stairs is a small library and study area. At top is a queen-sized sleeping pod under a

large skylight.

Design Team :

Sima Shahverdi, David mallot

Fabrication Team :

Chris Botham, James Earl, James Colman, Amit Adhikaree

with AI Space Factory

Fabrication Team :

Chris Botham, James Earl, James Colman, Amit Adhikaree

with AI Space Factory

Check out

MARSHA - HYDROPOD - KYTE

MARSHA

A NASA WINNING DESIGN FOR MARS

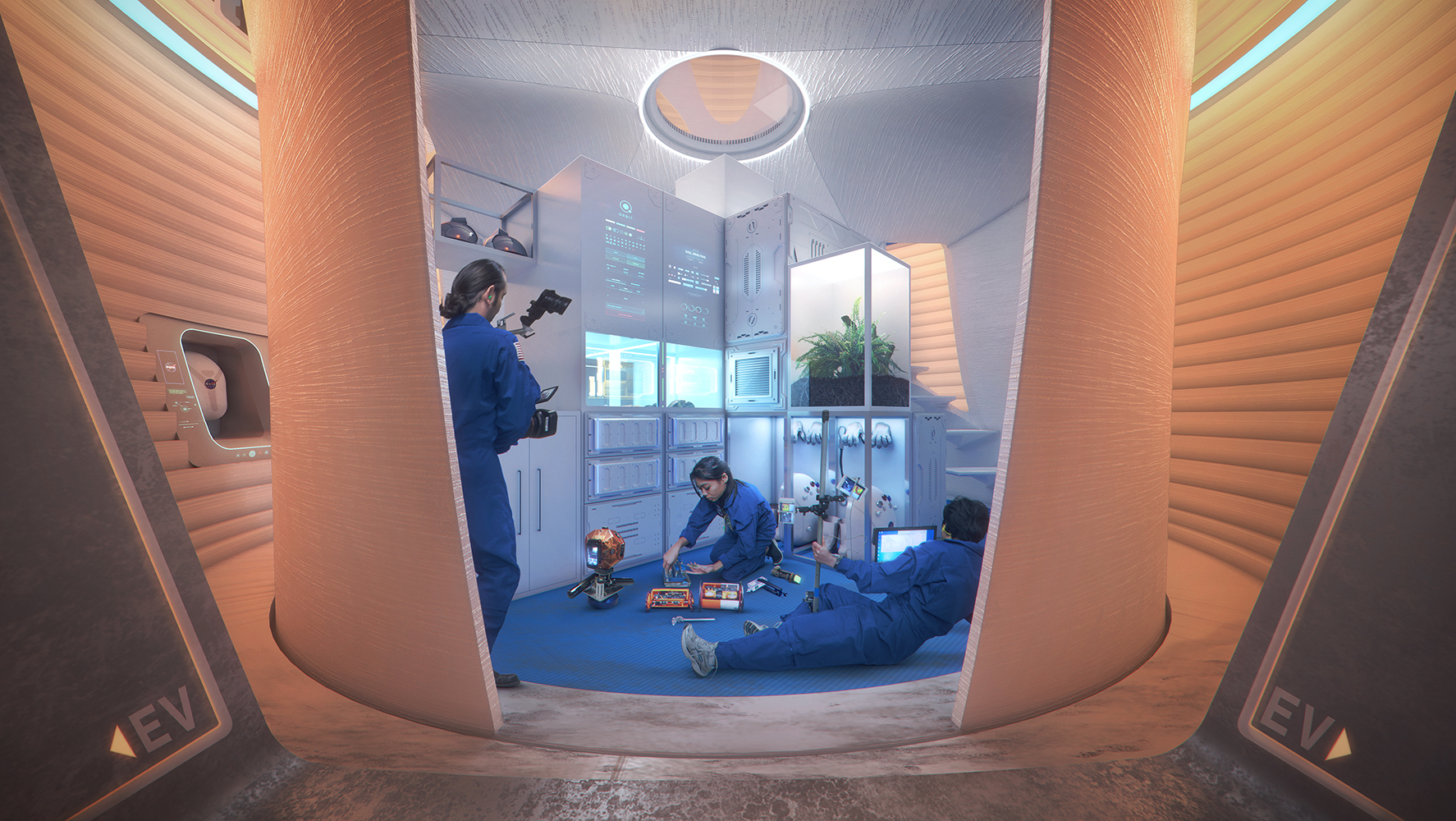

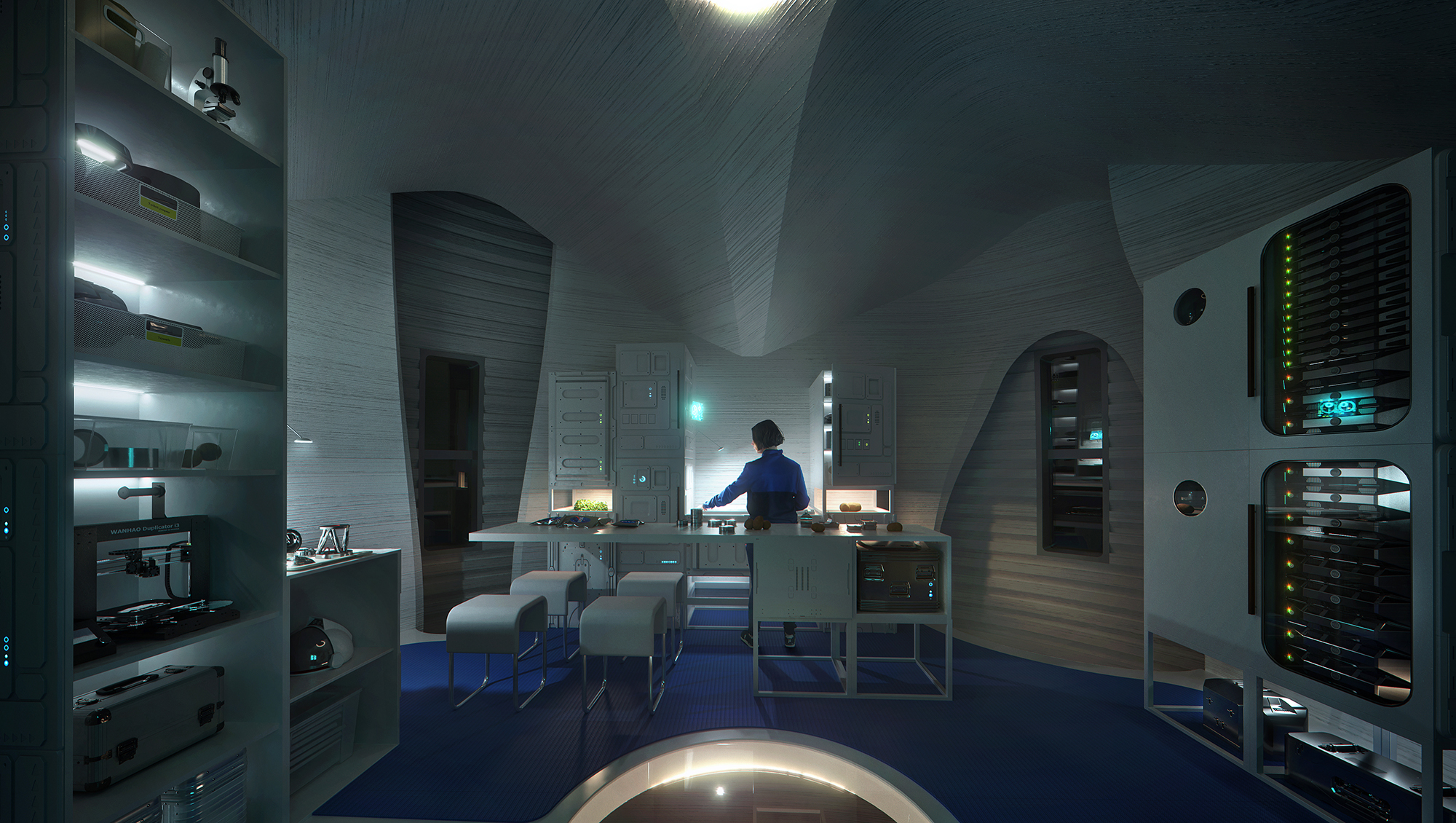

Marsha is a first-principles rethinking of what a Martian habitat could be. Marsha made us to rethink habitat design by responding to a completely different set of questions. Designing for Mars!

It is born of a careful response to the Martian environment and a synergy between architectural, structural and construction principles with the crew’s experience at the center.

Besides designing and modeling, I led the official multimedia submission to NASA and created the conceptual 3D printing construction animation.

Marsha is a first-principles rethinking of what a Martian habitat could be. Marsha made us to rethink habitat design by responding to a completely different set of questions. Designing for Mars!

It is born of a careful response to the Martian environment and a synergy between architectural, structural and construction principles with the crew’s experience at the center.

Marsha won the Nasa 3D printed habitat challenge Design Phase 1 in 2018

Besides designing and modeling, I led the official multimedia submission to NASA and created the conceptual 3D printing construction animation.

The first task for any Martian home is to hold an Earth-like atmosphere. A simple trade study of spatial and material efficiency shows that a vertically oriented cylinder is the best formal basis for a surface habitat.

The layout must reflect the strict flow of tasks typical of Space missions. But since sustained social and mental health are also mission critical, habitats should offer elements of surprise and literal room for the crew to slip outside of an overly prescriptive existence.

In this alien environment, construction sequence and materials must be rethought entirely.

On May 4th, after three phases and $1.6 million awarded the team participated in the Nasa Challenge at Caterpillar’s demonstration facility in Peoria, IL on 2019

Team AI SpaceFactory won the grand prize of $500,000 by successfully printing a 1:3 scale prototype of the primary structure

Design Phase 1:

Jeffrey Montes

Sima Shahverdi

David Malott

Tony Jin

Construction Phase 1&2:

Jeffrey Montes

Christopher James Botham

David Malott

Construction Phase 3:

Jeffrey Montes

Christopher James Botham

David Riedel

James Earle

James Coleman

Amit Adhikaree

with AI Space Factory

BACK TO TOP

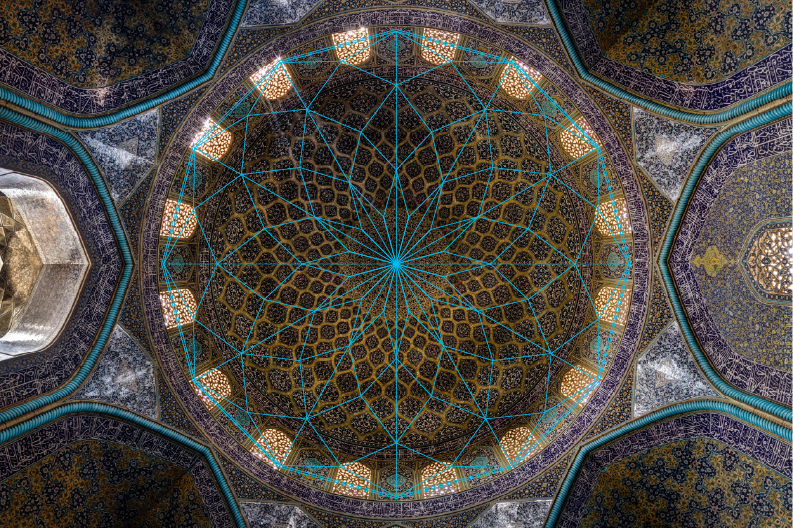

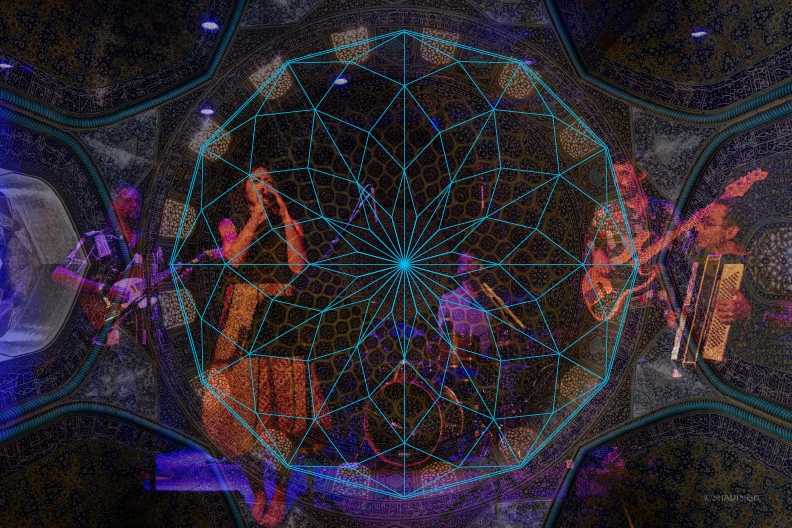

Echoes of a dome

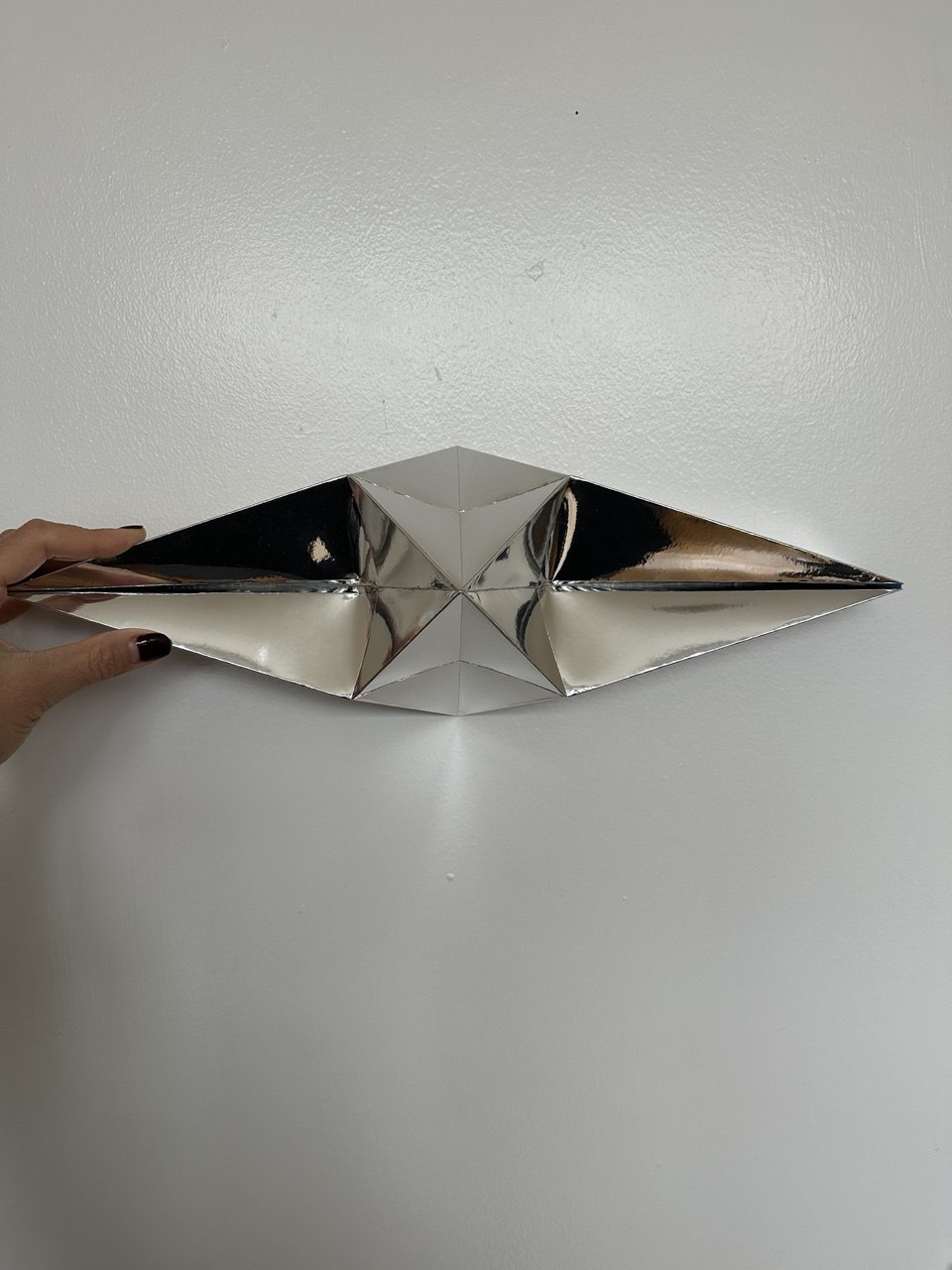

The first time I heard my voice out loud was under the Sheikh Lotfollah dome in Isfahan. The room answered back, and I still carry that echo. My memory is a mix of dome pattern, sound, and light through colored windows. My goal is to recreate this moment, where sound, light, and form carry the warmth and resilience of Iran.

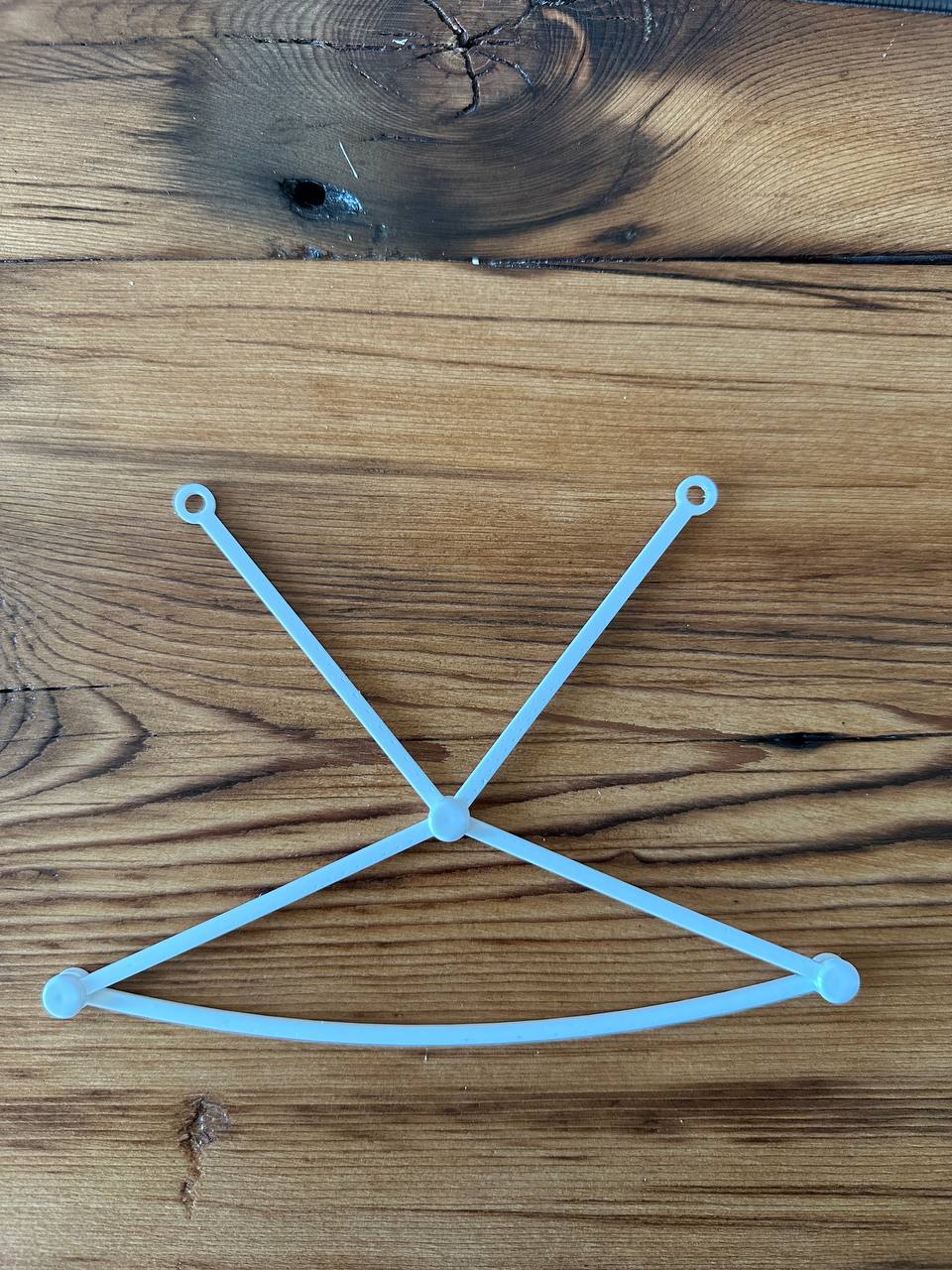

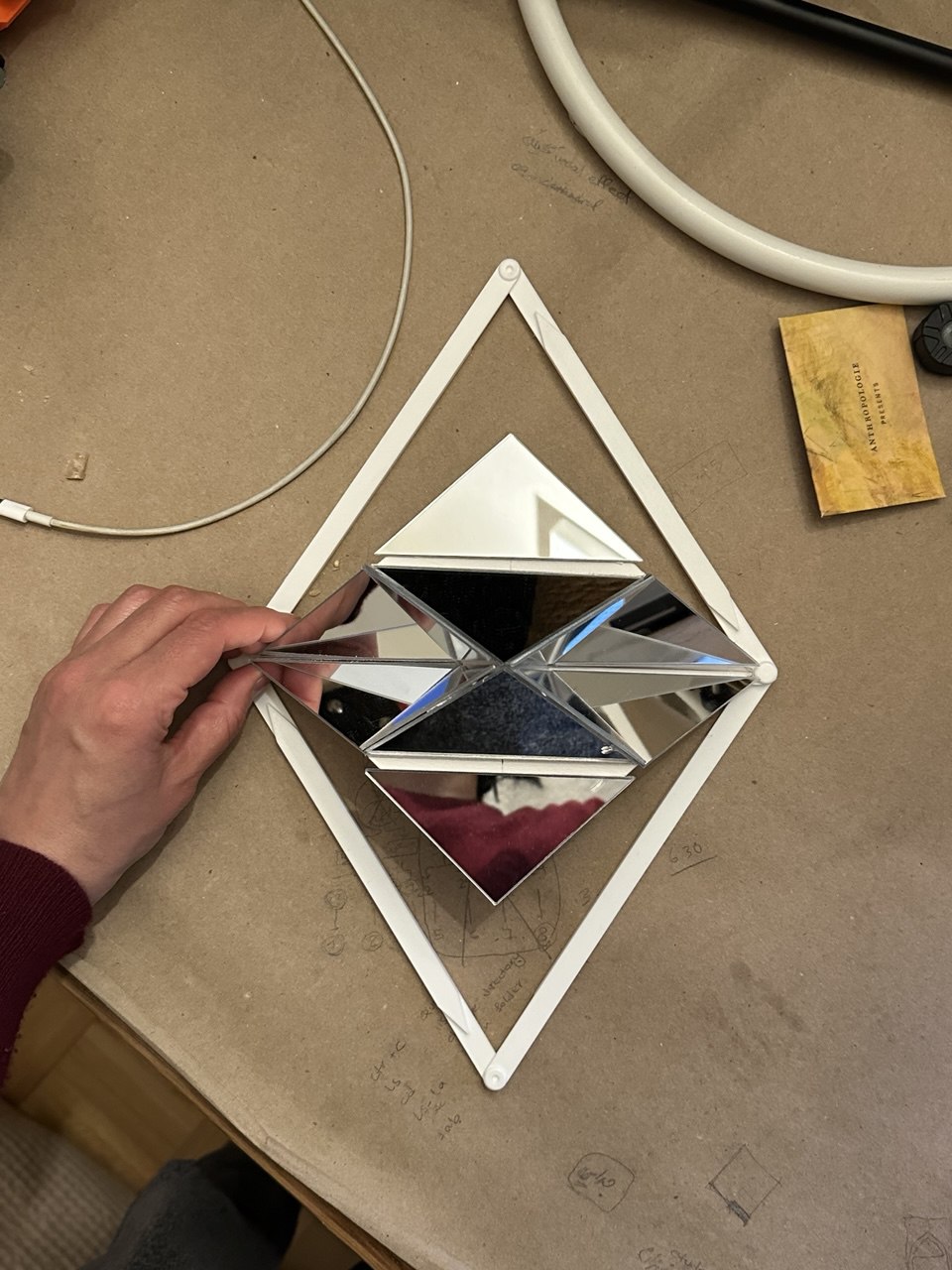

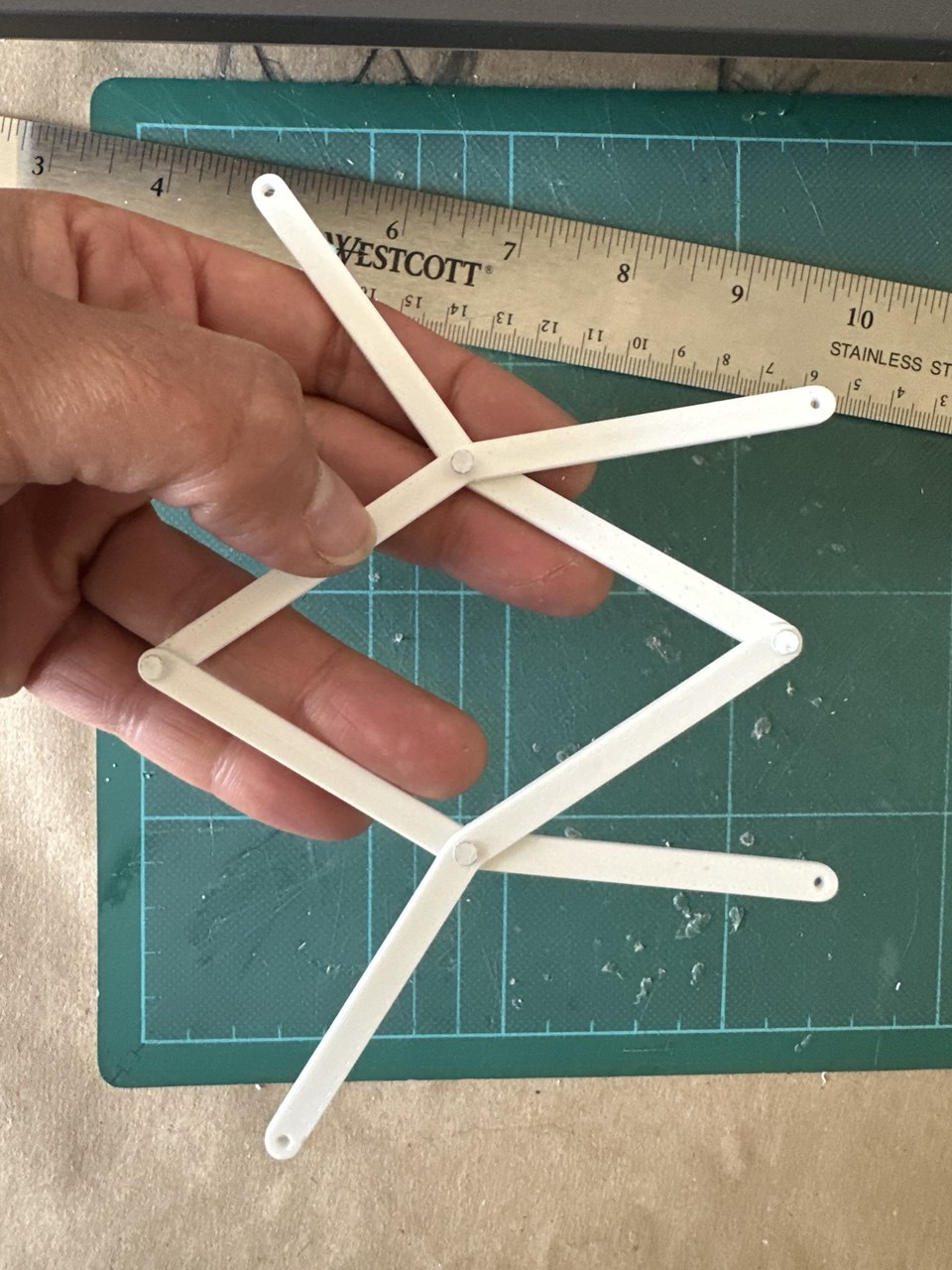

I am making a series of kinetic installations that respond to rhythm through moving joints and facets. I start with a kinetic dome, slightly concave and built with tessellations inspired by Iranian dome craft.

Scissor joints drive the motion; facets combine mirror and hand-colored acrylic sheets influenced by Iranian patterns.

As the dome moves, it reflects the space and casts colors on surrounding faces. It can be part of a solo set, a full-band show, or run on playback.

Team

Sima Shahverdi, Keith Berry, Ebrahim Poustinchi

UCLA - Technology Seminar - Julia Koerner

Sima Shahverdi, Keith Berry, Ebrahim Poustinchi

UCLA - Technology Seminar - Julia Koerner

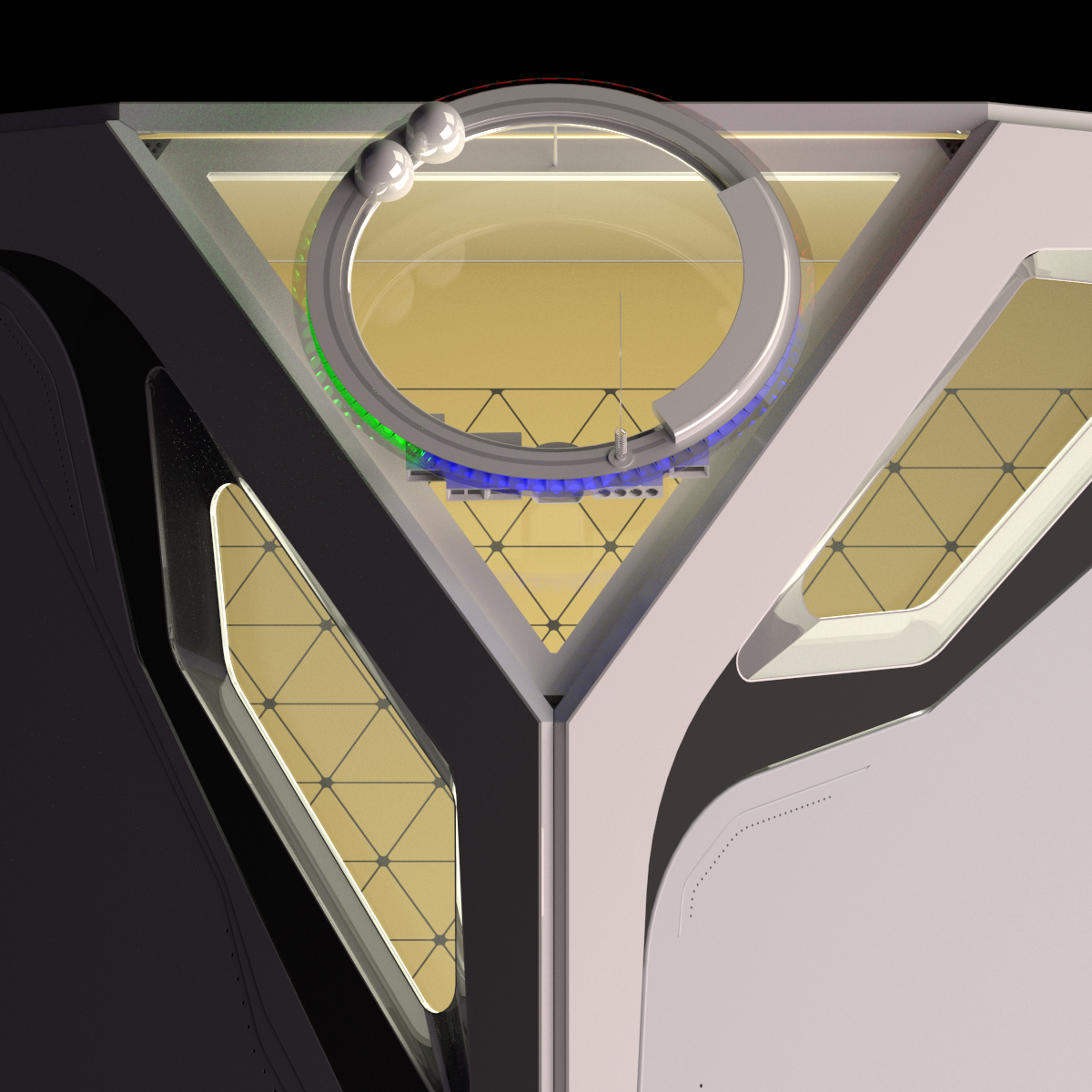

HYDROPOD

A modular and Reconfiguring Watercraft

Hydropod is a proposal that looks at a multi-purpose urban platform on water. Water surface would be one of the main platforms to consider as living space.

Like cells in tissue, or

ants in a colony, the individual hydropod is highly capable, robust and adapts

to its environment with power in numbers,

the fleet will be able to adapt and change to current needs placed on the

system.

Each craft was designed with a hexagonal plan that utilizes three-fold rotational symmetry. This symmetry allows for various patterns of clustering, increasing the flexibility of the system.

As a stand-alone piece, the craft design was broken into two parts; the hull, including everything below the floor plane, and the deck, including everything above the floor plane. The hull, like the drivetrain of a car, is standard to all craft, while the deck can be switched out to change the function, or ‘mod’, of each craft when necessary.

Deck:

1. Brain - sensing/communicating

2 . Petals - structural photovoltaic panels

3 . Floor System - adaptive wood tiles

4 . Structure - carbon fiber composite

5 . Foglights

Hull:

1. Battery

2. Ruderless Propulsion System

a.counter-rotating propellor array

b.water jet plenum-in/out

3. Active gyroscope array

4. Coarse pollution filter

The hull, like the drivetrain of a car, is standard to all craft, while the deck can be switched out to change the function, or ‘mod’, of each craft when necessary.

Fog Harvesting Mode of Hydropods

TEAM:

SIMA SHAHVERDI

JEFFREY MONTES

CHRIS BOTHAM

WITH AI SPACE FACTORY

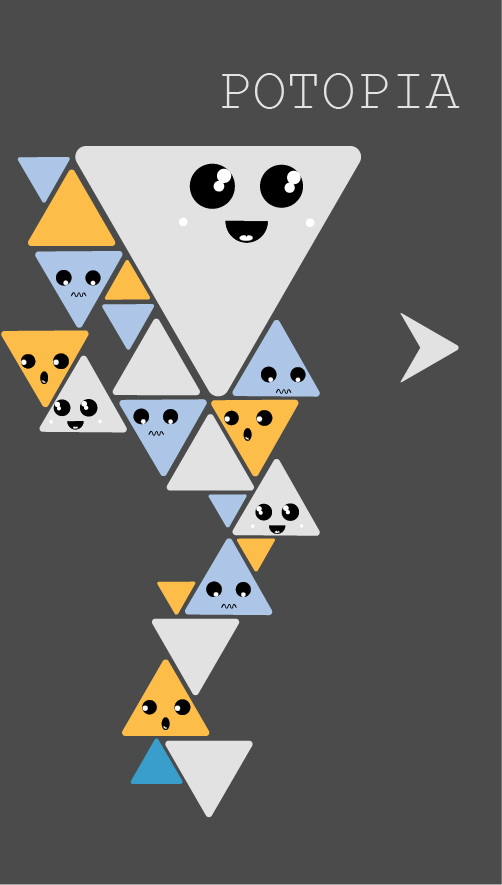

Potopia

SMART MODULAR PLANTER SYSTEM

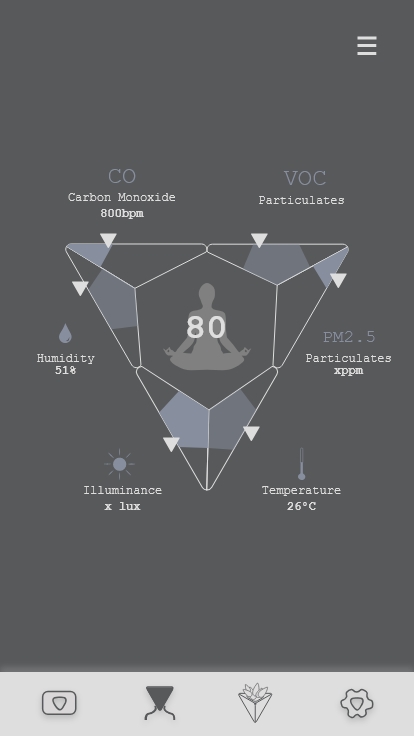

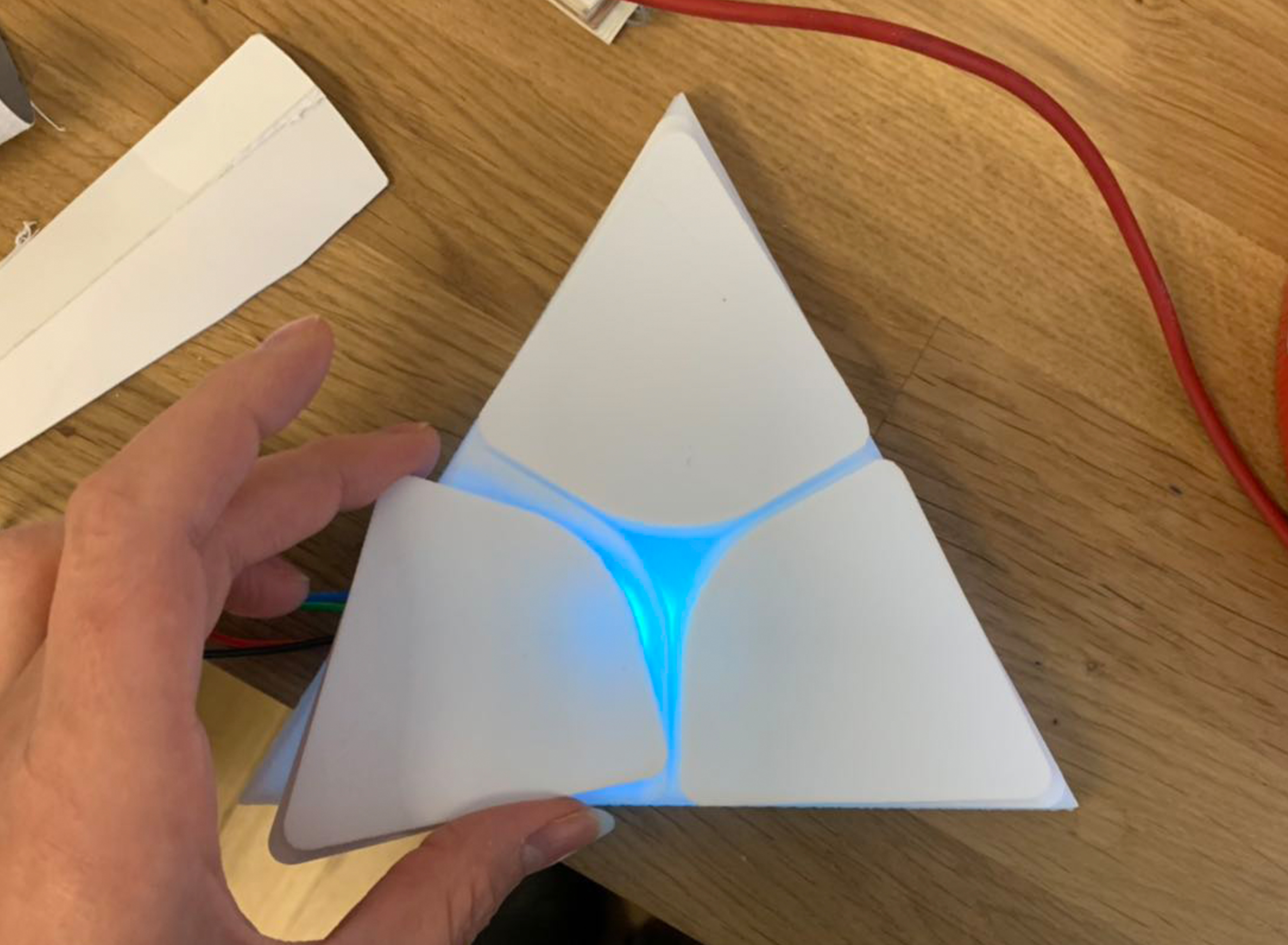

Potopia is a modular smart planter pot system. It helps busy plant-lovers understand what their plants need. This smart pot communicates with user through an LED indicator located at its nose. Through different light colors it can ask user for more or less water, fertilizer or sun light. Because it is a modular system, the user can customize the configuration.

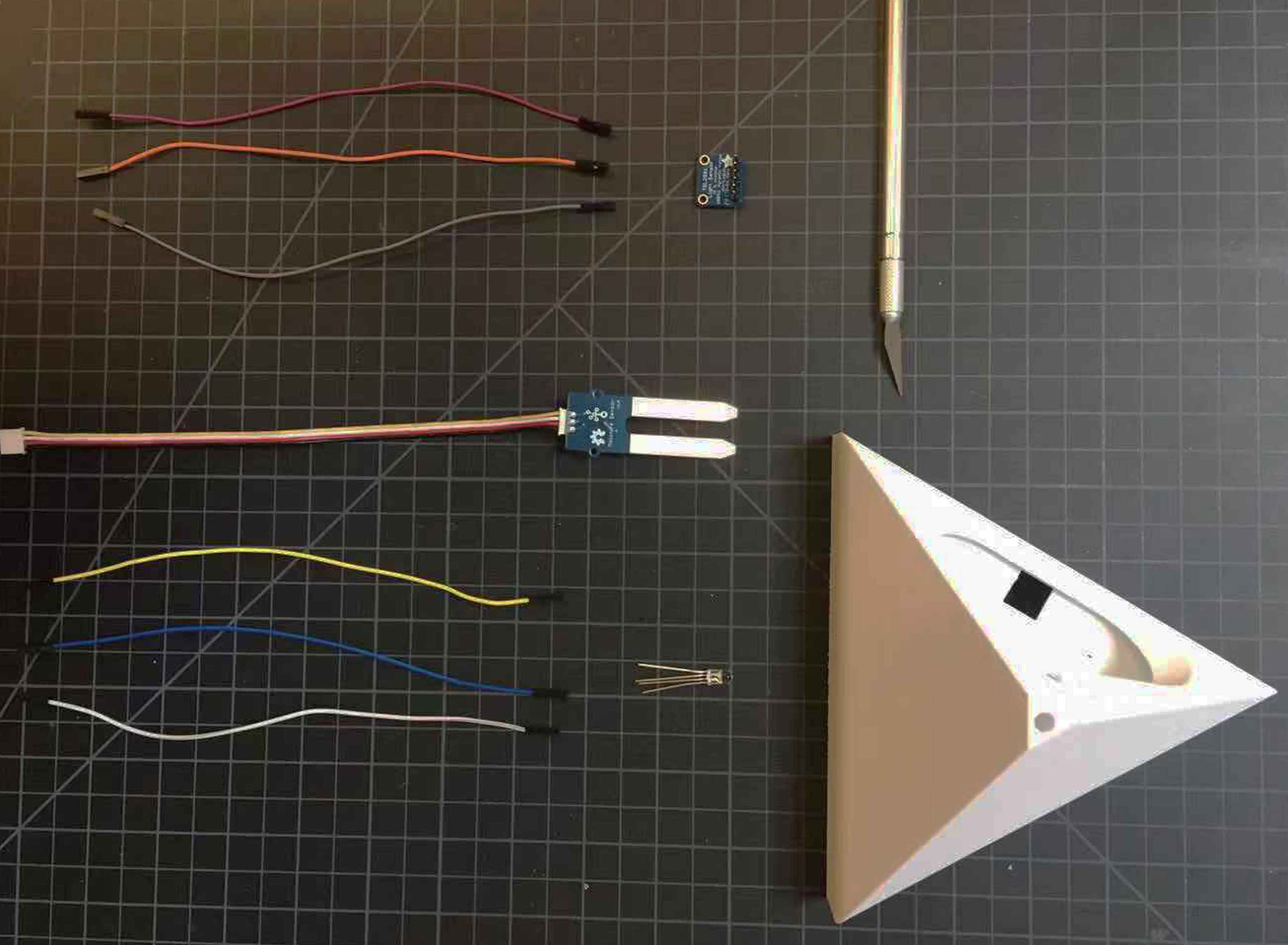

I lead the product design team with a close collaboration with development team in R&D

![]()

![]()

There are some suggestions for the configurations that comes with the package. It can be mounted on the interior or exterior walls

![]()

Potopia is a modular smart planter pot system. It helps busy plant-lovers understand what their plants need. This smart pot communicates with user through an LED indicator located at its nose. Through different light colors it can ask user for more or less water, fertilizer or sun light. Because it is a modular system, the user can customize the configuration.

I lead the product design team with a close collaboration with development team in R&D

There are some suggestions for the configurations that comes with the package. It can be mounted on the interior or exterior walls

Potopia helps busy plant-lovers understand what their plants need.

Potopia comes in a package of six. It also contains a pack of mixing pot, seed and potopia app. The app allows the user to get updates about their plants without physically being present

Potopia took shape through different iteration and rapid prototyping using in house PLA 3d print method. By embedding a temperature and a soil humidity sensor inside the planter skin, environmental data can be collected. This data later will be monitored by a central microcontroller located in the mother module and would be processed. The result of the processed data determines if the plant needs more or less water, if it is cold or hot and if it is time to repot and add fertilizer

Potting mix packaging and some behind the scene studies

Design and development Team:

Sima Shahverdi

David mallot

james Colman

Amit Adhikaree

with AI SpaceFactory

Sima Shahverdi

David mallot

james Colman

Amit Adhikaree

with AI SpaceFactory